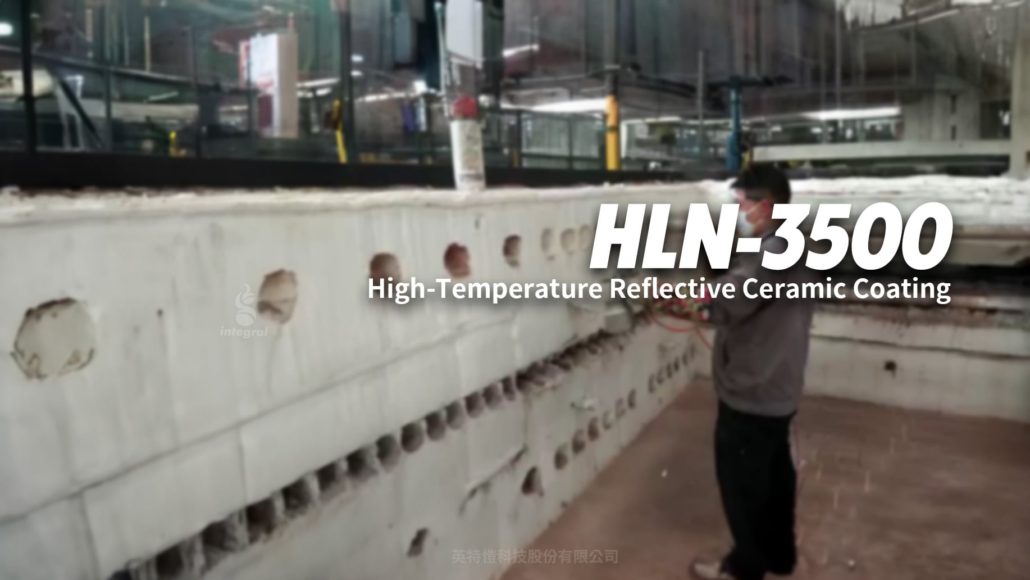

HLN-3500 High-Temperature Reflective Ceramic Coating

HLN-3500 High-Temperature Reflective Ceramic Coating is a special energy-saving coating with high-temperature resistance, strong reflectivity, low thermal absorption, excellent corrosion resistance, and high wear resistance. It is formulated using a special inorganic silicate composite system as the film-forming material, with the addition of transition metal oxide, zirconium oxide, rare earth oxide Y2O3, and other fillers.

The cured coating forms a dense ceramic radiative layer with a good, high, and stable infrared emissivity. In environments above 800°C, the coating improves heat exchange inside the furnace, enhances combustion temperature and uniformity within the furnace chamber, allowing for more efficient fuel combustion. This, in turn, increases the thermal efficiency of refractory materials, reduces energy consumption, conserves energy, and extends the service life of furnace linings.

Characteristics

| Item | Performance Parameter | Remarks |

|---|---|---|

| Container Condition | Uniform, no clumping, flocculation, or precipitation | – |

| Color | Black-green | – |

| Adhesion | Grade 1 | – |

| Flexibility (Bending) | 4mm | The smaller the diameter of the bend, the greater the elongation on the outer surface of the coating. Flexibility is best at a 1mm diameter bend and worst at 20mm. |

| Coating Hardness | 5H | – |

| Infrared Emissivity | 0.95 | Ratio with blackbody radiation at the same temperature |

| Heat Resistance and Salt Spray Test (24h) | No bubbling, peeling, cracking, or rusting | – |

| Oxidation Resistance | No corrosion, no noticeable oxidation color | – |

| High-Temperature Test | 1900°C | – |

- Strong infrared emissivity, good corrosion resistance, high hardness, and superior wear resistance at high temperatures.

- Can be diluted with water.

- To accommodate different substrate surfaces, it needs to be paired with a primer.

- Simple application method.

Applications

- Furnace

- Furnace chamber

- Boiler lining

- Coal-fired furnace

- Oil and gas furnace

- High-temperature kiln

- High-temperature electric furnace, etc.

Project Achievements

| Year | Client | Project Name | Construction Location | Industry |

|---|---|---|---|---|

| 2023 | Taiwan Styrene | Spray Painting High-Temperature High-Reflective Coating | Kaohsiung | Petrochemical |

| 2022 | Taiwan Chlorine | Furnace Refractory Material Spray Coating Energy-Saving Paint Project | Kaohsiung | Petrochemical |

| 2021 | Taiwan Chlorine | Furnace Refractory Material Spray Coating Energy-Saving Paint Project | Kaohsiung | Petrochemical |

| 2021 | Taiwan Styrene | Interior Spray Painting High-Temperature High-Radiation Coating | Kaohsiung | Petrochemical |

| 2020 | Kun Electric Heating Machinery | High-Temperature High-Radiation Coating Spray Painting | Kaohsiung | Machinery |