NUKOTE Polyurea multi-functional product

Our polyurea products are manufactured by the American company Nukote. They are pure polyurea dual-component materials. The polyurea product series is created through the reaction of diphenylmethane diisocyanate and amine compounds, resulting in a highly durable, resilient, and flexible material.

It can be applied to various substrates such as concrete, steel, wood, and more. It possesses features like waterproofing, high wear resistance, impact resistance, and chemical resistance.

It can be used over a wide temperature range (30~120℃) and exhibits rapid curing properties. These superior qualities make it an excellent protective coating with a long service life.

Characteristics

- 100% solid content, solvent-free, environmentally friendly in production and application.

- Fast curing speed, allowing for quicker construction progress. Subsequent work can commence 30-45 seconds after spraying.

- Strong adaptability to various environmental conditions, suitable for application at different temperatures, and minimal impact on coatings and surfaces when applied in humid environments.

- Excellent mechanical properties, including high tensile strength, elongation at break, and adhesive strength.

- Seamless finish after application, suitable for various materials, and highly flexible and durable.

- Resistant to aging, impact, and wear.

- Outstanding corrosion resistance and excellent acid and alkali resistance.

- Exceptional waterproofing performance.

Applications

- Can be used in water resources and wastewater treatment plants.

- Suitable for large-scale and temporary site floor coatings.

- Applicable in water treatment plants and seawater desalination plants.

- Useful in hydro, thermal, natural gas, or nuclear power plants.

- Suitable for tunnels and sewer pipelines.

- Effective in waterproofing landfills.

- Applicable in civil and construction site waterproofing and floor slip resistance.

- Ideal for building foundation waterproofing, external waterproofing of underground structures, and protection.

- Suited for impact-resistant explosion-proof spaces. Corrosion and impact resistance for various underground pipelines.

NUKOTE ST Wear-resistant Materials

Purpose: To protect the steel plates on the barrage surface from being damaged by debris during typhoons and heavy rainfall and to reduce wear and tear on the steel plates, thereby extending the lifespan of the barrage surface.

Purpose: To repair the flood diversion channel, which has been eroded by high-velocity water flow and sediment particles, leading to the erosion of the surface concrete and exposure of steel reinforcement. The use of wear-resistant materials aims to extend the service life and reduce the maintenance frequency.

NUKOTE FR fire-resistant material

In modern society, there are still many wooden buildings, and they require suitable fire-resistant coatings. According to the fire resistance requirements of fire-resistant panels from the largest cooling tower manufacturer in the United States (MIDWEST COOLING TOWERS), they must comply with the fire protection standard ASTM E84 class 1 as a basis.

The fire protection standard ASTM E84 is based on Flame Spread Index (FSI) and Smoke Developed Index (SDI). Class 1 compliance means FSI < 25 and SDI < 450.

Applications

- Electrical poles

- Wood

- Steel structures

- Fire protection and waterproofing of concrete

- Fire lining in tunnels

- Warehouse floors with highly flammable products

- Cargo holds and general ship hull lining

- Encapsulation and protection of fiberglass, polystyrene, and PU spray foam

NUKOTE PA II Impact-Resistant Polyurea

NUKOTE MI Military Bulletproof and Blast-Resistant Polyurea Material

Characteristics

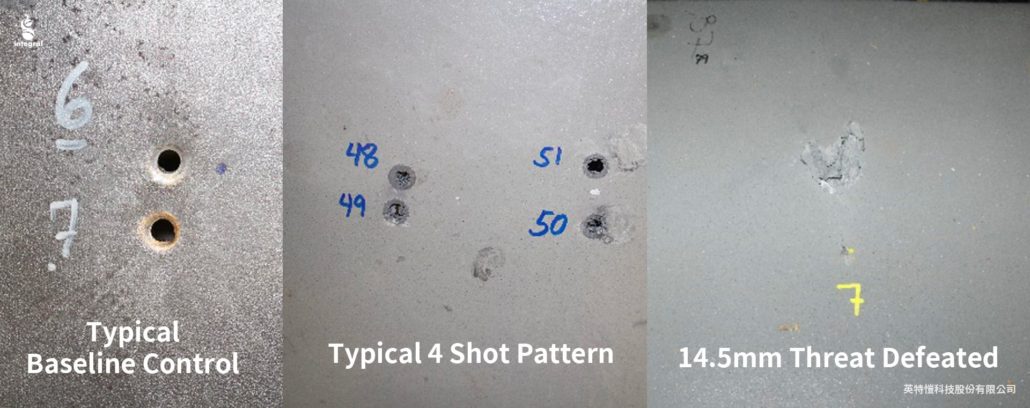

- The NUKOTE MI series products are specially developed polyurea materials designed to meet the requirements of military bulletproof and blast protection. They provide exceptional, concealed, and invisible protection for military personnel.

- MI polyurea maximizes the strength and durability of bulletproof vests while minimizing the impact of flying debris following high-power explosive blasts.

- This material can be applied to various substrates such as concrete, steel, fiberglass, and aluminum, forming a rubber-like membrane. It helps mitigate the force of explosions and aids in securing the substrate together, offering a perfect balance of strength and flexibility. It maintains structural integrity and provides excellent impact resistance even under extreme conditions, such as car bomb explosions, missile attacks, or drone strikes.

- MI polyurea enables military vehicles to withstand gunfire, landmine explosions, improvised explosive devices, and other harmful threats.

Applications

- Armored vehicles for troop transport and light armored attack vehicles

- Armored vehicles for the Coast Guard and light attack ships

- Explosion mitigation for inspection checkpoints, bases, and ammunition storage bunkers

- Explosion mitigation for naval facilities and air force bases

- Blast protection for government, military, and private buildings with steel or concrete structures, including aircraft

- Protection of storage tanks containing flammable liquids

- Corrosion protection for water and fuel oil tanker trucks

- Use in emergency vehicles such as fire trucks, police cars, ambulances, trucks, and vans

Project Achievements

| Year | Owner | Project Name | Construction Location |

|---|---|---|---|

| 2022 | Aggregate Truck Bed Polyurea Spray | ||

| 2022 | GoodLots | Steel Structure Fireproof Board Installation | Nankan |

| 2022 | GoodLots | Steel Structure Fireproof Board Installation | Zhongli |

| 2022 | GoodLots | Steel Structure Fireproof Board Installation | Xinzhuang |

| 2022 | GoodLots | Steel Structure Fireproof Board Installation | Beitou |

| 2022 | GoodLots | Steel Structure Fireproof Board Installation | Chiayi |

| 2021 | Geng Enterprise | Coal Transport Pipe Wear-Resistant Lining Spray | |

| 2021 | Taiwan Benzene○ene | Coal Chute Improvement Abrasion-Resistant Spray | |

| 2021 | Trust○ Industrial | Intercontinental Storage Construction Project Tank Bottom Corrosion Protection | Kaohsiung |

| 2020 | Taiwan Electric○ | Chute Repair | Taichung |

| 2020 | Taiwan Benzene○ene | GSA Spray Gun Wear-Resistant Coating | |

| 2020 | Taiwan Electric○ | Steam and Electric Plant Impeller Coal Feeder Wear-Resistant Coating | Kaohsiung |

| 2019 | Rong○ Engineering | Reservoir Silt-Proof Tunnel Abrasion-Resistant Project | Nanhua Reservoir |

| 2019 | Ming○ Systems Technology | Check Dam Sand Outlet Channel Guidance Repair and Dam Surface Abrasion Project | |

| 2018 | Ministry of Economic Affairs – Water○ Bureau | Weir Dam and Fishway Abrasion Project | Kaohsiung |

| Taiwan Kuo○ | Underground Pipeline Lining Repair Project | Chiayi |