UNIFRAX Silplate Mass

Silplate Mass is made from polycrystalline ceramic fibers and high-purity refractory oxides. It requires no dilution and can be used as-is. It is suitable for use in environments with temperatures of up to 1500°C. After drying, it forms a highly flame-resistant surface that is not easily worn down, even at high airflow velocities. It has a low shrinkage rate, reducing the likelihood of cracks in concrete and ceramic fiber insulation materials.

Silplate Mass can be used to protect:

- Ceramic fiber wool bricks

- Insulation and refractory castables

- Insulating and refractory bricks

- It is also used for repairing cracks and filling areas with deteriorating concrete.

Characteristics

- Sealing gaps and localized repairs in refractory bricks.

- Increasing the gas flow velocity of refractory materials up to 60 m/s.

- Enhancing the wear resistance of ceramic fibers.

- Reducing the shrinkage of ceramic fibers.

- Minimizing heat loss due to shrinkage gaps in refractory materials.

- Extending the lifespan of castable refractories.

Case Study: Improvement of Cracking Furnace in 2021

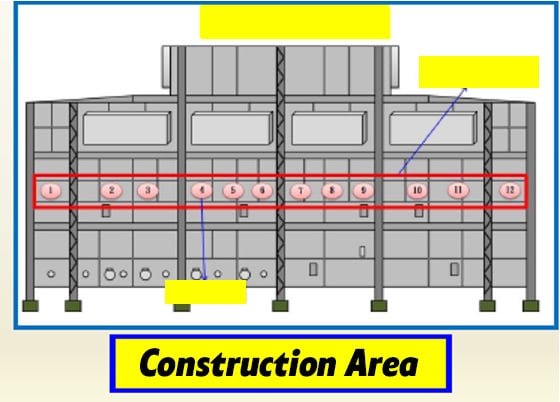

In order to improve the high-temperature impact on the cracking furnace walls, the client commissioned the purchase of high-temperature wear-resistant coating, Silplate Mass. The application of Silplate Mass was carried out during the annual maintenance period. Initially, the planned construction location was the entire row of furnace walls on the east side of Cracking Furnace 2F, from burner number 1 to 12.

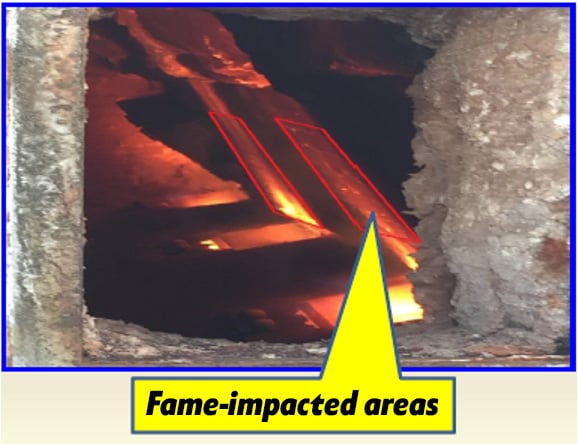

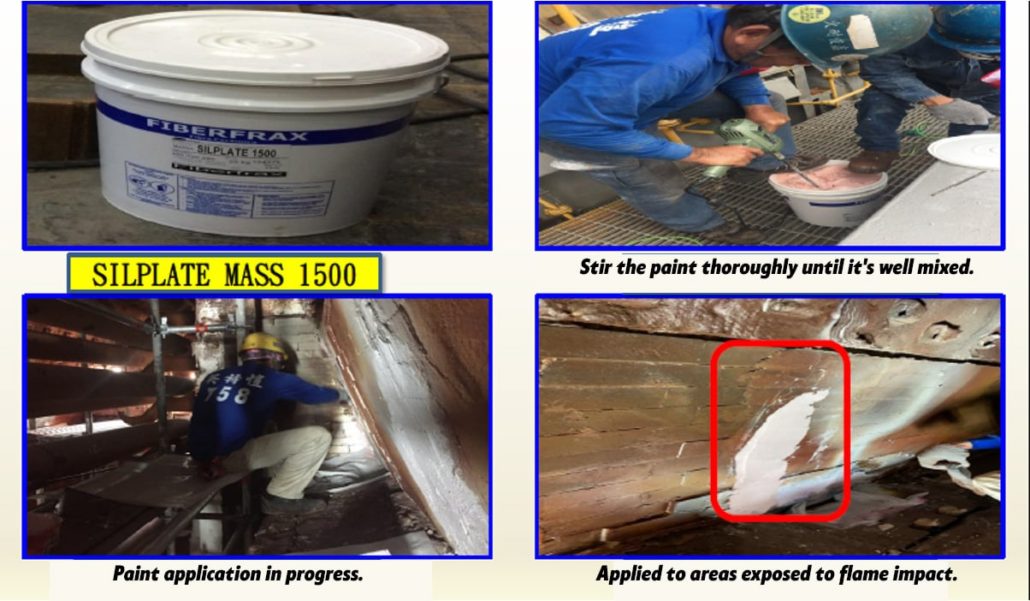

However, considering the numerous areas of abnormal temperatures and the limited duration of the shutdown period, it was not feasible to completely replace the refractory materials in all the abnormal areas. After discussions with the manufacturer, it was decided to apply the coating only to the areas of the furnace walls exposed to flame impacts.

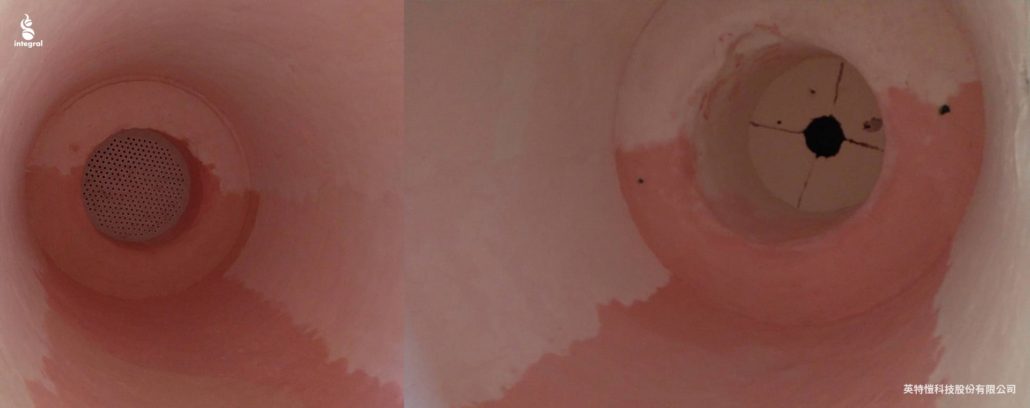

Before Construction

During Improvement

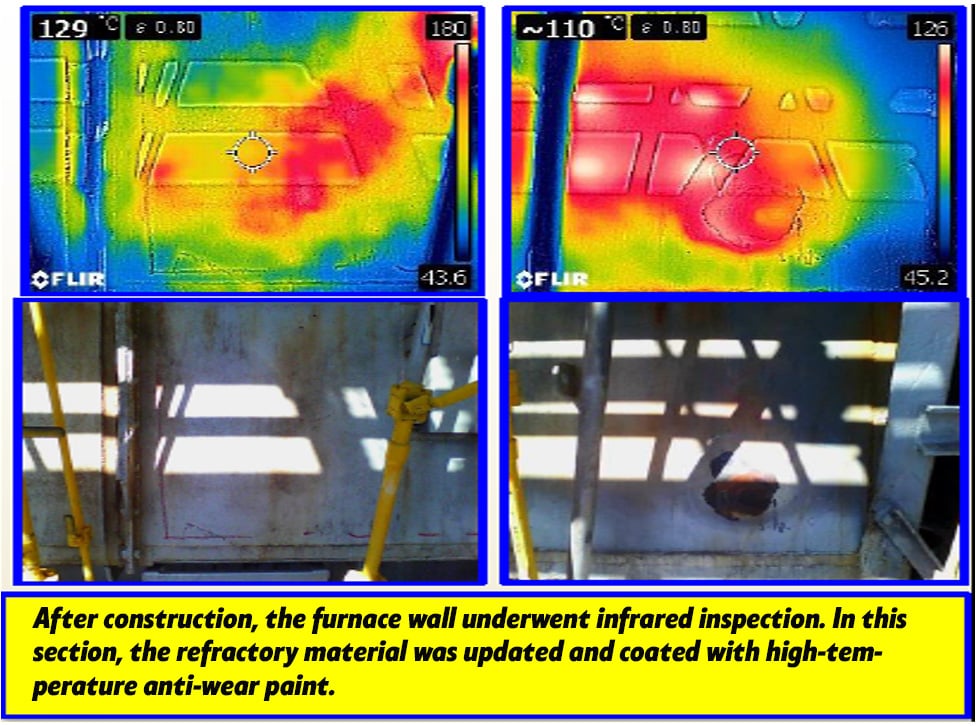

After Construction

Project Achievements

| Year | Owner | Project Name | Construction Location |

|---|---|---|---|

| 2021 | Company X Industry | Oxidation Furnace Duct Brick Joint Filling | Changhua |

| 2021 | Company X Industry | Sealing Gaps in Combustion Furnace Lining | Yunlin |

| 2017 | Taiwan Oil Refining and Research Institute | Purchase of Silplate Mass | Kaohsiung |

| 2021 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Yunlin |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Yunlin |

| 2021 | Taiwan Chlorine Vinyl Industry | Furnace Refractory Repair | Kaohsiung |

| 2021 | Taiwan Plastics Industry | Furnace Refractory Emergency Repair | Kaohsiung |

| 2021 | Taiwan Plastics Industry | EW03 Refractory Mud Repair | AE Plant |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Kaohsiung |

| 2023 | Taiwan Plastics Industry | Incinerator Refractory Repair | Yunlin |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Yunlin |

| 2023 | Taiwan Plastics Industry | Solidified Fireproof Mud | Yunlin |

| 2022 | Taiwan Corporation | AE Plant Waste Oil Area | |

| 2022 | Taiwan Corporation | VCM Incinerator 611 | Yunlin |

| 2022 | Taiwan Corporation | VCM Incinerator 621 | Yunlin |

| 2021 | Base Oil Plant Burner Repair | ||

| 2021 | Taiwan Corporation | VCM Incinerator | Kaohsiung |

| 2021 | Taiwan Corporation | Combustion Furnace | Kaohsiung |

| 2021 | Taiwan Corporation | Cracking Furnace | Kaohsiung |

| 2020 | Chang Corporation | EDA Combustion Furnace | Yunlin |

| 2019 | Taiwan Corporation | Waste Liquid Boiler | |

| 2019 | Taiwan Corporation | VCM Plant Waste Gas Incinerator | Yunlin |

| 2017 | Taiwan Corporation | Waste Gas Boiler Burner |